PNEUMATIC PRESS

We are Manufacturer, Supplier, Exporter of Pneumatic Press like Seal Pressing & Sizing SPM, Pneumatic Assembly Machines, Glove Latch Assembly, Assembly SPM, Pin Pressing SPM, Seal Press and our setup situated in Pune, Maharashtra, India.

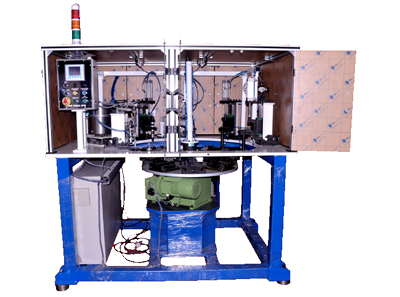

Seal Pressing & Sizing SPM

• Two Station Linear Indexing Machines

• After Loading the Job first Presence of Grooves are Confirmed by Vision Sensor

• Then Two Seal are Pressed Automatically

• After Pressing the Seals again Confirmation is done by Vision Sensor

• Then Job Moves Bak Wards where in Sizing of Seal is done

![]()

Designed by : MID I Hosted by : PBD I Promoted by : GID